Flow nozzle

Spraytech Systems Flow Nozzle is used in typically high-velocity, non-viscous, erosive flow. They are suitable for determining the flow rates of fluids at high temperature and high pressure.

Flow Nozzles have a smooth elliptical inlet leading to a throat section with a sharp outlet. Restriction in the fluid flow causes a pressure drop, which relates to the flow rate by applying Bernoulli's equation.

There are three types of Flow Nozzles

- ISA 1932, with corner taps

- ASME long radius, low beta ratio (0.25 < ß < 0.5), with throat tap

- ASME long radius, high beta ratio (0.25 < ß < 0.8), with radius taps (D & D/2)

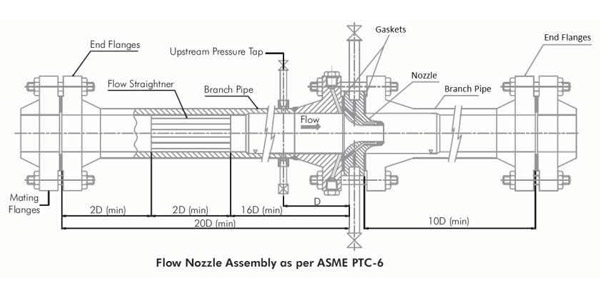

ASME long radius, low beta ratio Nozzle with throat taps is used in steam turbine performance test As per ASME PTC-6 code.

ISA-1932 nozzle can be mounted with carrier ring or in between flanges with corner taps.

Long radius nozzles are normally with weld - in branch pipe with radius taps, Can be also mounted in between flanges.

To avoid welding of dissimilar metals, nozzles are also installed in the pipe with holding ring.

Salient features & benefits

- Widely used for high pressure & high temperature steam flow

- Useful for flow measurement at high velocities

- Rounded Inlet not subject to wear or damage, extending product life

- Better sweep-through effect for debris and liquids, eliminate damming effect

- Lower susceptibility to erosion

- Extended product life with no moving parts

Quick Links

- PRDS

- Orifice assemblies

- Integral assemblies

- Differential pressure flow meter and transmitters analog and digital

- Multistage orifice assemblies

- Single seat globe control and manual valves

- Averaging pitot tubes

- V notch ball control valve

- Flow nozzle

- Positioners and position transmitters

- Flow venturi

- PID Sanitary globe control valve

- 3 way globe control valve

- Self actuated pressure and flow and temperature regulators

- Manual valves ball, butterfly and gate type

- Sight flow indicators

Contact Us

+91 9987584555 +91 9920568555 +91 9987681932 +91 9920830555VISITORS CAN QUICKLY FIND THE RIGHT INFORMATION.

Contact Us